Why America Will Lose Semiconductors

Tangible bi-partisan solutions for solving a national security crisis.

The US has always been the world leader in semiconductors: design, manufacturing, and the tools to produce them. Semiconductors are the base of all technological innovation in computing and information technology. Without them, companies such as Amazon, Google, Microsoft, Meta, Apple, and Tesla would not exist. The US has slowly been losing its dominance over the semiconductor industry over the last couple of decades. In recent years, the rate of loss has been accelerating. If it is lost, then the foundational building block of modern technology is lost, and the US will cede its overarching technology advantage. In this article we will discuss the major causes of this problem and offer solutions which should be bipartisan in nature.

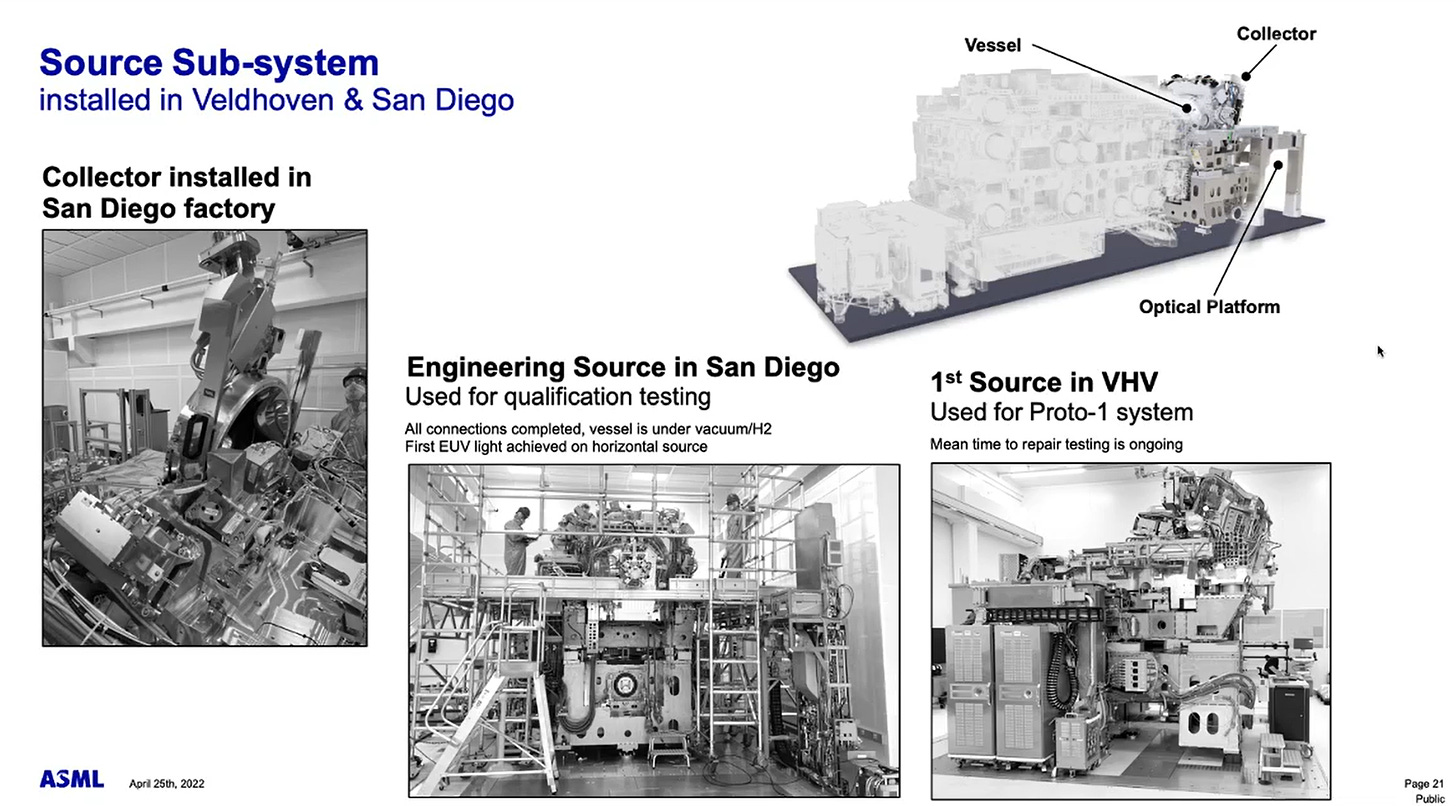

Before we get into the problem, let’s talk about the current state of the US’s semiconductor dominance. Most of the largest semiconductor equipment, design, and software companies are based in the US or have critical engineering in the US. In the equipment space, Lam Research, Applied Materials, and KLA are based is of the US. ASML, the widely known leader in lithography, does much of their critical engineering for the EUV Source and EUV Collector out of San Diego. These technology assets and teams come from the acquisition of San Diego based Cymer. ASML pays royalties to the EUV-LLC whose membership includes multiple US national labs. Without these tools, it is impossible to manufacture chips.

The critical software needed to be used to design chips is called EDA and it all comes from the US. Cadence, Synopsys, and Mentor Graphics (now owned by Siemens) are located in the US. Without this software, it is impossible to design modern chips.

American companies like Texas Instruments and Intel hold leading market shares in their respective fields while manufacturing their own chips. The 4 largest companies that design chips for external sale and use contract manufacturers are also American. They are Qualcomm, Broadcom, Nvidia, and AMD.

But that dominance is shifting away to countries that pose as geopolitical risks. US share of chip manufacturing is at an all-time low. The US will lose the semiconductor industry unless immediate action is taken. This is a national security crisis.

The US has been the hallmark of innovation through entrepreneurship, education, and making large investments. All three of these tenets are eroding, partially due to the private market’s attitude and partially because the government’s policies incentivize certain behaviors. The shift is occurring in favor of countries that have favorable government policies, regulatory support, focus on STEM higher education, and a general cultural recognition of the importance of semiconductor manufacturing.

Entrepreneurialism in Semiconductors

Entrepreneurialism is what innovated and semiconductors in the first place. Ever since the invention of the transistor at Bell Labs, startups in Silicon Valley created and defined the modern semiconductor industry. Unfortunately, entrepreneurism in the semiconductor industry is falling away.

SemiEngineering.com, one of the leading publications in the semiconductor industry, tracks monthly semiconductor and semiconductor adjacent industry startup fundraising by company headquarters location. Their data is compiled in the table below for May, but other months look very similar. This trend is terrifying for prospects of American hardware dominance. Not only is most of the assembly done in China, but the most well-funded startups in the semiconductor field and the most IPOs in the semiconductor field are occurring there well.

While startups and IPOs don’t necessarily indicate innovation, they are one of the corner stones of it. Not all startups will succeed, and it’s very likely the stricter funding models of US based startups will mean they are more likely to succeed, but the disparity is a big issue. America isn’t the land of entrepreneurship anymore, despite continuing to dominate other areas of the world such as Europe. It’s China.

Why are there so few semiconductor startups in the US?

The US private market of venture capital and angel investing is completely off its rockers investing in software platform based “tech” companies. While this type of investing is fine, these same venture capital and angel investors have completely ignored the semiconductor and hardware space. We here at SemiAnalysis have seen it firsthand as we have helped a few firms in the semiconductor industry raise money. It’s extremely difficult to convince venture capitalists to invest in startups, even if they have promising technology and exceptional track records.

The private market has a strong prejudice against hardware startups. Semiconductors in general have higher startup costs, and the market potential is limited in comparison to a platform-based tech company. US based venture and angel investors that require them tend to think in terms of tens or hundreds of billions of dollars addressable markets. They want software platforms that can have a few dozen employees with the potential to scale to billions in revenue. There can only be so many Instagram’s, Uber’s, Shopify’s and Airbnb’s though. Hardware entrepreneurship is needed even if it doesn’t meet the wild dreams that US based venture and angel investors have. A friend of SemiAnalysis, Jay Goldberg has written about this phenomenon on his newsletter in posts titled Hard or Soft, and Hard or Soft with Math.

Semiconductor investments are a tragedy of the commons style of situation. No private entity will invest in basic infrastructure since no single entity will reap all possible rewards. Semiconductor manufacturing and design capacity are modern day infrastructure for technology and software, with the similar requirement that these kind of infrastructure projects require government incentives and regulatory support to thrive. The US government must assist the semiconductor startup industry by offering incubators and accelerators through the National Science Foundation.

Investment Crisis in Semiconductors

Startups are not the only place where investment is lacking. This problem exists at the largest firms as well. As such, US share of semiconductor R&D has dropped drastically and domestic chip production has fallen from 40% to below 15%. Investment is not encouraged by our financial markets or our government policies. We will showcase the plights of US policies, which incentivizes buybacks and dividends over investment, with a few examples.

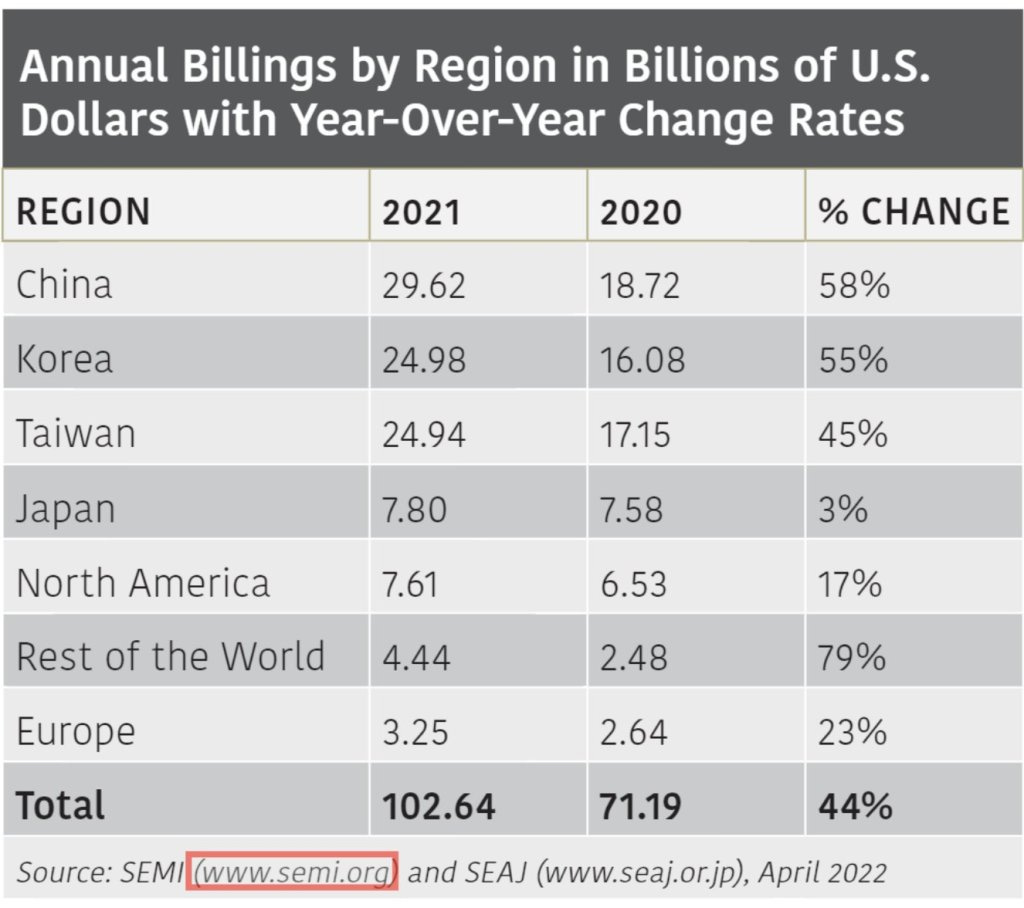

First let’s discuss the crux of the issue. The chart below shows total semiconductor wafer fabrication equipment spending by region. It shows that China by far is building the most fabs, which is driven by their favorable tax and regulatory policies as well as massive subsidies. The US is a tiny share of worldwide spending. If the current rate of spending holds, then in a decade, the US will be fabricating less than 10% of the world’s semiconductors and China will be fabricating nearly 30% of them.

The US national, state, and local governments have created tax and regulatory policy that makes investing in new manufacturing capacity for semiconductors incredibly difficult. It takes mountains of money and many years to even get through the process of permitting and approval to being a project in the US. Furthermore, while these policies intend to protect the environment, they actually don’t. They simply slow down the process and increase costs.

This contrasts with other nations who offer tax credits and outsized deductions for investments in semiconductor tools. They offer streamlined processes for permitting and approval of the fabrication facility. They protect the environment with proactive punitive actions for polluting companies. They allow entire developments of new apartments, homes, and businesses to quickly crop up around semiconductor facilities, so workers do not have to spend huge portions of their paycheck on living expenses, which in turn lowers costs for companies and increases the standard of living for the entire community.

The US must make it more advantageous to a company’s stakeholders to invest heavily in new capacity instead of paying dividends and performing stock buybacks. One solution is by offering a permanent option for a 100% deduction of chip manufacturing equipment, tools, and other associated capital expenditures in the 1st year of purchase. Other industrial equipment such as trucks serve as precedent for such a policy.

To be clear, such a policy would only make one part of a multifaceted incentive package targeted at equalizing policy with other nations. China has gone as far as offering tax holiday for up to 10 years to domestic semiconductor companies. While such a drastic measure is unrealistic in the US, it should serve to underscore the criticality of policy changes needed when our biggest geopolitical rival is willing to take such a measure.

This gap in policy is what has caused Micron, the largest US based memory manufacturer, to offshore manufacturing out of the US. Micron now produces the majority of their memory chips in Singapore and Taiwan, despite their R&D hub and original manufacturing facilities being located in the United States. The two largest memory manufacturers in the world, SK Hynix and Samsung, are headquartered in South Korea. Although they are generally considered equal or behind Micron in technology, SK Hynix and Samsung hold larger market share. This is partially the byproduct of various South Korean semiconductor policies which incentivize larger investments in fabrication capacity. South Korea is only accelerating on their incentives in the semiconductor industry with their K-Belt initiative. This policy is a geographic ring-fenced low-tax and pro-R&D area with tool and R&D tax reimbursements.

Furthermore, a tax credit must be applied to R&D expenditures. Currently, US tax policy does not have one that matches many Asian nations. Instead, it incentivizes minimizing R&D as much as possible to fund stock buybacks, dividends, and financially engineered acquisitions.

Broadcom is an example of the broken US tax policy incentivizing the wrong behavior for the semiconductor industry. Although Broadcom has been a stellar stock to invest in and they still lead in some areas of technology, their innovation strategy has been very negative for the industry as a whole. Broadcom generally keeps a very tight lid on all expenses, including R&D growth. Meanwhile, they have increased prices for chips and software where they enjoy a near monopoly status. Lastly, they use these profits they generate to acquire more innovative leading companies with products and technologies that they can apply this formula to. The policy is colloquially known by those in the semiconductor industry and investors as the “Hock Tan Flywheel,” named after their CEO who engineered this strategy. We won’t even get into that time where they moved their headquarters to Singapore for a number of years for tax optimization, but it was also a result of poor US policy.

Another example of poor investment related policy is that of Intel in the prior decade. They were on top of the world in terms of semiconductors. Instead of innovating in new areas of semiconductors design and manufacturing, they focused on lowering capital expenditures and total spending as percentage of revenue. They used their profits to buy back shares and pay larger dividends. Shareholder elected board members who cheered on and specifically encouraged this behavior. There is certainly a lot more to the story of Intel’s downfall including technological missteps and a toxic corporate culture, but the flaws in US tax policy and financial markets were certainly a big contributor. Nowadays, Intel has realized their mistakes and cut stock buybacks to 0. They are investing every dollar they can, but they simply cannot hold a candle to the sheer scale of fab spending these other countries hero’s such as TSMC and Samsung.

An example of good targeted policy is with Wolfspeed and the state of New York. New York assisted Wolfspeed via tax reimbursements and other subsidies in order to build the world's largest Silicon Carbide semiconductor fabrication facility. New York as a result is a world leader in a type of chip that is used heavily in electric vehicles, there were thousands of high paying jobs created, and the State University of New York has a full fledged program for research and education that prepares people for continued innovation in this field.

Education in Semiconductors

Even if the startups and production facilities were in the US, there is now a severe shortage of skilled workers in the field. By 2025, this shortage is projected to be as high as 300,000 workers. Educated and skilled personnel is a cornerstone of innovation, and without them, the job cannot be done.

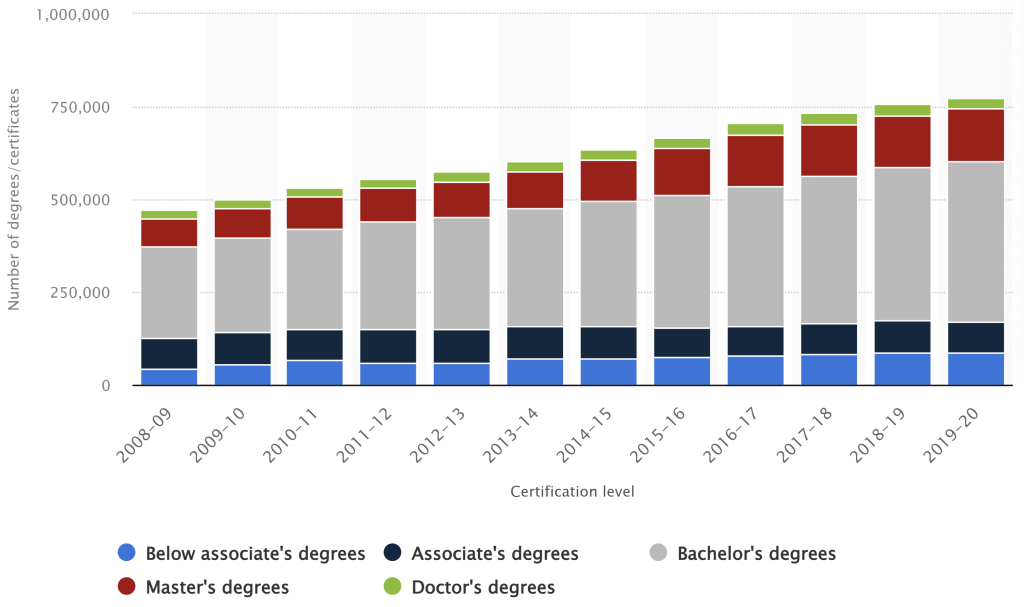

Most Americans who pursue a higher education do so in a non-STEM field. While not a negative in and of itself, this is a huge concern when viewed in light of the expected growing shortage of skilled workers in the semiconductor industry. Over 5 million people were granted degrees/certificates at postsecondary institutions in the US, yet not even 1/5th were in STEM according to the chart below from Statista.

2/3 of STEM PHD students in the US are foreigners. They were able to get student visas for their education, yet many of them have a very difficult time immigrating after their education despite hoping to do so. China has nearly 5 million people graduating with STEM degrees annually, population size differences make the gap between China and the US impossible to fill with domestic population alone.

The US must make it easier for educated people around the world to immigrate. It was much easier at other points in US history, which was part of the recipe for the US outpacing the rest of the world in innovation. The concept of brain drain is very real, and the best and most qualified in the world must be allowed to move to the US.

China doesn’t just allow semiconductor workers to immigrate, they explicitly find people they want and go after it. There are multiple state owned enterprises which offer a highly specific and prestigious quality of life to engineers moving from Taiwan. They provide spacious accommodation near semiconductor hubs and personal tax advantages alongside the targeted immigration. Many of these amazing engineers from Taiwan would come to the US if they had the opportunity, even without the state sponsored lifestyle.

Furthermore, of the pool of US STEM graduates, the number specifically going to fields related to semiconductors, manufacturing or design, is a tiny fraction of the total. These semiconductor related STEM programs are vastly underfunded. The federal and state governments have not promoted them in any way. Meanwhile, competing nations have subsidized these programs to a massive degree. This in turn increases the total number of available minds dedicated to their respective semiconductor industry which then allows more innovations.

The US post-secondary education system subsidizes all degrees and certificates by generally the same amount even though there are some professions with large shortages of skilled workers. Our education system needs to account for the effective skill allocation based on industry gap in labor demand when subsidizing education costs or promoting certain fields.

The public and media perception of the field does not help with this matter either. Being a chip architect, process integration engineer, or board designer are not the career most children and young adults aspire to have. It’s just not sexy. Meanwhile China idolizes the semiconductor industry, going so far as to create a glorifying TV show.

Part of the lack of interest in semiconductors is due to the culture of repairing and tinkering with computing devices. Many in the semiconductor industry fell in love with the industry when they first opened up a computer. For example, my story of obsession with the semiconductor industry started when I got an Xbox 360 for Christmas. A few months later, it broke due to a defect known as the “Red Ring of Death”. After doing research online, I came across a home repair known as the “Penny Trick” which involves opening the device. This sparked my love for the industry. Unfortunately, the culture of repairing computers, game consoles, and smartphones, is dying in the western world due to a variety of legislative and company specific roadblocks.

In Taiwan and China, this culture flourishes. It is very easy to get parts for devices, whether it be displays, batteries, memory, or even entire mainboards. People can go the Guanghua market in Taipei City, Taiwan, Huaqiangbei in Shenzen, China, or numerous other markets across these countries and purchase any component or tools associated with repairing common consumer electronic devices.

Implementing right to repair policies would bring the US on par with these nations and should have bipartisan support. It is good for the consumer’s because they have more freedom of control over the devices they purchased and allows their devices to last longer. It is good for the environment because less electronic waste is produced. It is good for the semiconductor industry because it makes more people become interested in opening computers and becoming interested in how they work. Taiwan and China can do this because their governments allow the right to repair movement to flourish, and the US needs to match them if we want members of our youth to fall in love with this industry as well.

Actions Congress Must Take To Save The Semiconductor Industry

Congress must immediately pass multiple bi-partisan legislative efforts if it wants to bring the US semiconductor industry back to the forefront of the world.

Congress must immediately pass the CHIPS Act which was first introduced over 2 years ago. They should also add guardrail provisions that restrict any recipient of CHIPS act funds from reaching companies that are expanding in China. The $52B here is still a drop in the bucket compared to the over $250B of subsidies that SemiAnalysis has tallied up from the Chinese government in the form of tax policy, direct + indirect grants, local joint ventures, and subsidized loans, but it is a start.

Congress must immediately fix the US tax code to bring it on par with other nations whose companies currently have an unfair advantage. This can be achieved by implementing an optional 100% bonus depreciation for chip manufacturing equipment, tools to make wafer fabrication equipment, and other associated capital expenditures related to the design or production of semiconductors in the year of purchase. Congress must also implement a permanent tax credit for these groups of investments to match that of other east Asian countries.

Congress must immediately fix the US permitting and regulatory lock which severely lengthens the amount of time and increases costs for creating semiconductor manufacturing facilities.

Congress must immediately fix the R&D spending gap by adding a tax credit for R&D related to semiconductors.

Congress must immediately fix the startup crisis by directing the National Science Foundation to create a startup incubator and accelerator targeted to the semiconductor industry.

Congress must immediately fix the education disparity by funding semiconductor and semiconductor adjacent post-secondary education programs.

Congress must immediately fund and create a US based semiconductor research facility similar to Europe’s IMEC.

Congress must immediately fix the skilled semiconductor worker shortage by allowing skilled semiconductor workers to immigrate to the US.

Congress must immediately pass right to repair laws to increase interest in the hardware industry thereby increasing consumer freedom and protecting the environment.

Congress must immediately pass legislation to protect against state sponsored corporate espionage, forced IP transfers, and hacks in the semiconductor industry.

If these actions are taken, we are confident that the ingenuity and innovation of America can be unleashed, and the US can stay at the apex of the semiconductor industry. If these actions are not taken, we are confident that the US will further erode its leadership in an industry with ever increasing importance to national security.

A well written article, and as a retired electrical engineer I can really relate to almost every sentence. I wanted to work on semiconductors (it was the major of my MSEE degree BTW), but all my employed friends went into software because it was apparently sexier and certainly paid more. Worse, what little federal money that was available for hardware seemed to all go to military contracting companies (think "Star Wars" initiative) and that wasn't something I wanted to work on.

Finally, about the STEM engineering problem. When I turned 38 my project got cancelled. It took me a few years to find anything remotely in my field of expertise. The industry seems only interested in "a few years of experience" engineers. Meanwhile the executives of several failed companies I worked for got paid millions every year. America needs a serious attitude adjustment!

"Part of the lack of interest in semiconductors is due to the culture of repairing and tinkering with computing devices. [...] Unfortunately, the culture of repairing computers, game consoles, and smartphones, is dying in the western world due to a variety of legislative and company specific roadblocks."

This is SO true. I became interested in the industry decades ago because I liked to take things apart and see how they worked. This culture is critical to keep people interested in hardware!